Automatic Barrel Heat Transfer Machine

The machinery adopts servo motor syterms to control, providing stable printing effect. This barrel transfer machine could directly integrated with an injection molding machine to achieve full automation. The machine can print 1 ~ 25 liters of barrels, easily to change product transferring. While just need to input three numbers of the barrel size information, the machine could complete transferring job itself, which reduces working labors.

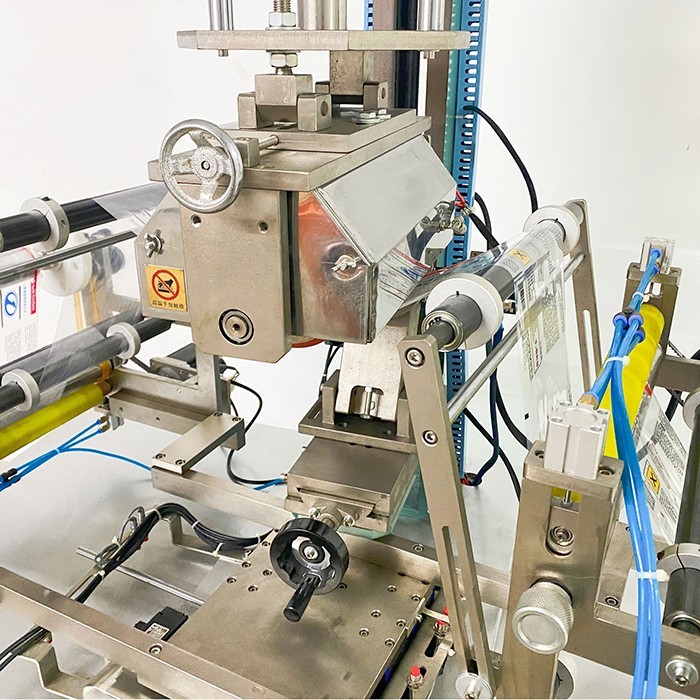

1: The Transfer Machine is equipped with fully automatic controlled PLC system.

2: Machine adopts high hardness aluminum material, precision processed by large CNC computer gongs,which enables the entire machine is elegant and durable.

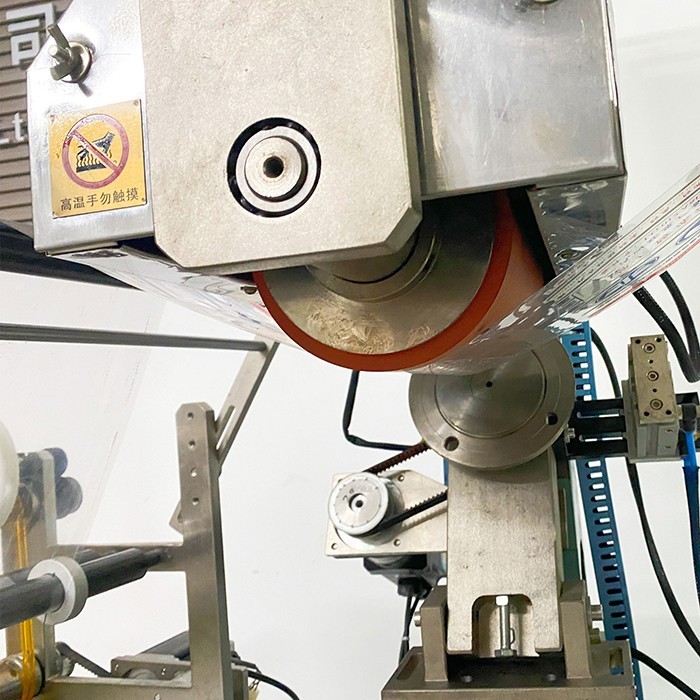

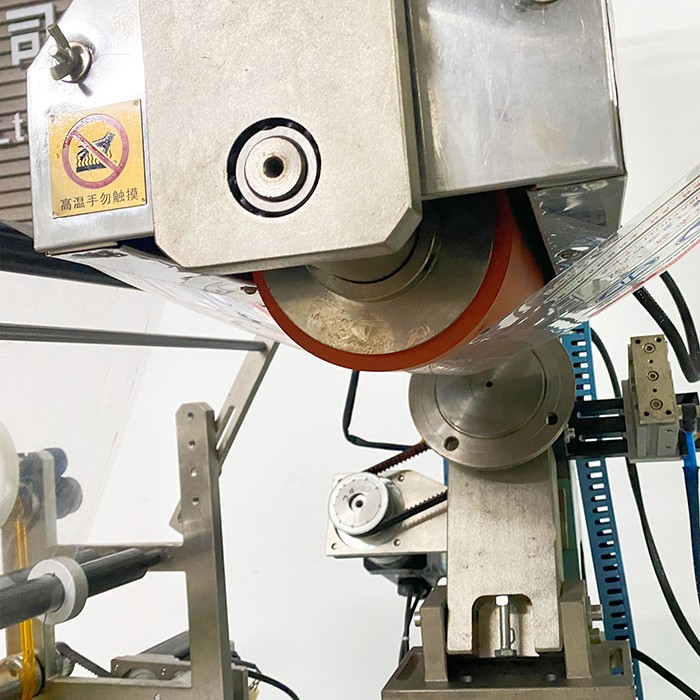

3: The hot stamping head is driven by cylinder to ensure high pressure, balance and stability.

4: The hot stamping head height, temperature, pressure, and speed are adjustable, and the hot stamping delay and roll paper delay are adjustable to meet different printing requirements.

5: Adopting a stepper motor to control the material receiving movement, dual speed film receiving ensures the stability of the hot stamping paper movement and the accuracy of positioning.

6. The machinery is equipped with a servo-driven correction structure design. It will automatic adjust if there is deviation during film movement (the servo-driven correction feature needs to be optionally configured).

7: Magnetic powder tension structure controls the movement of the hot stamping paper, ensuring the stability of the hot stamping paper tension.

8: The transfer Machine equipped with an automatic feeding and discharging structure, without the need for manual film application, greatly improving production efficiency.

9. The operation of the machine, fixture movement, and the front, back, left, and right swing of the transfer film are all controlled by high-precision servo motors, effectively solving the problem of wrinkling

10. High printing accuracy, interface misalignment +/-0.5mm

11. External foot switch with three operation options: manual/automatic/foot.

12. The printing position of the barrel body is controlled by high-precision optical fiber, with automatic positioning function to prevent the barrel from not being placed in place and fracturing the rubber roller; Can effectively control the defect rate

13. The servo motor is used to control the mechanical rotation. The mechanical rotation is stable and can be controlled digitally to realize the intelligent rotation of the jig.

FA Printing Machine Manufacturer Limited

FA Printing Machine Manufacturer Limited