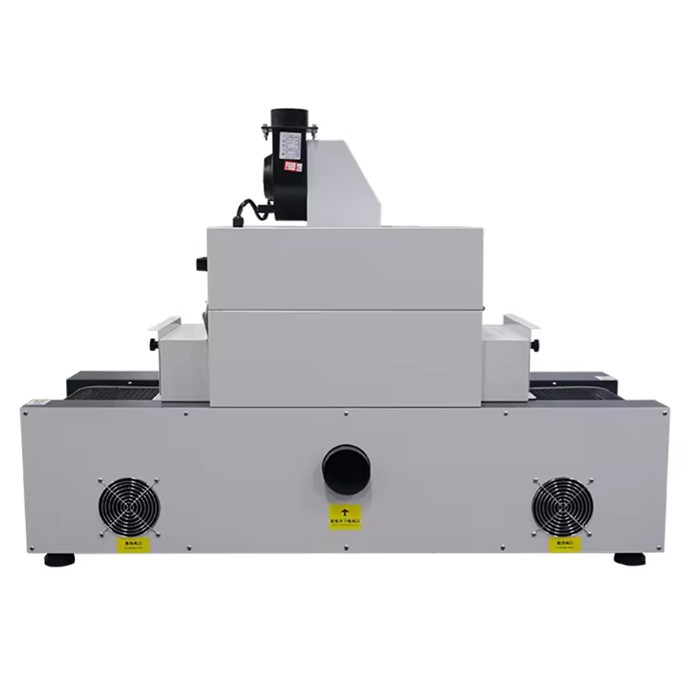

UV Glue Varnish Drying Equipment

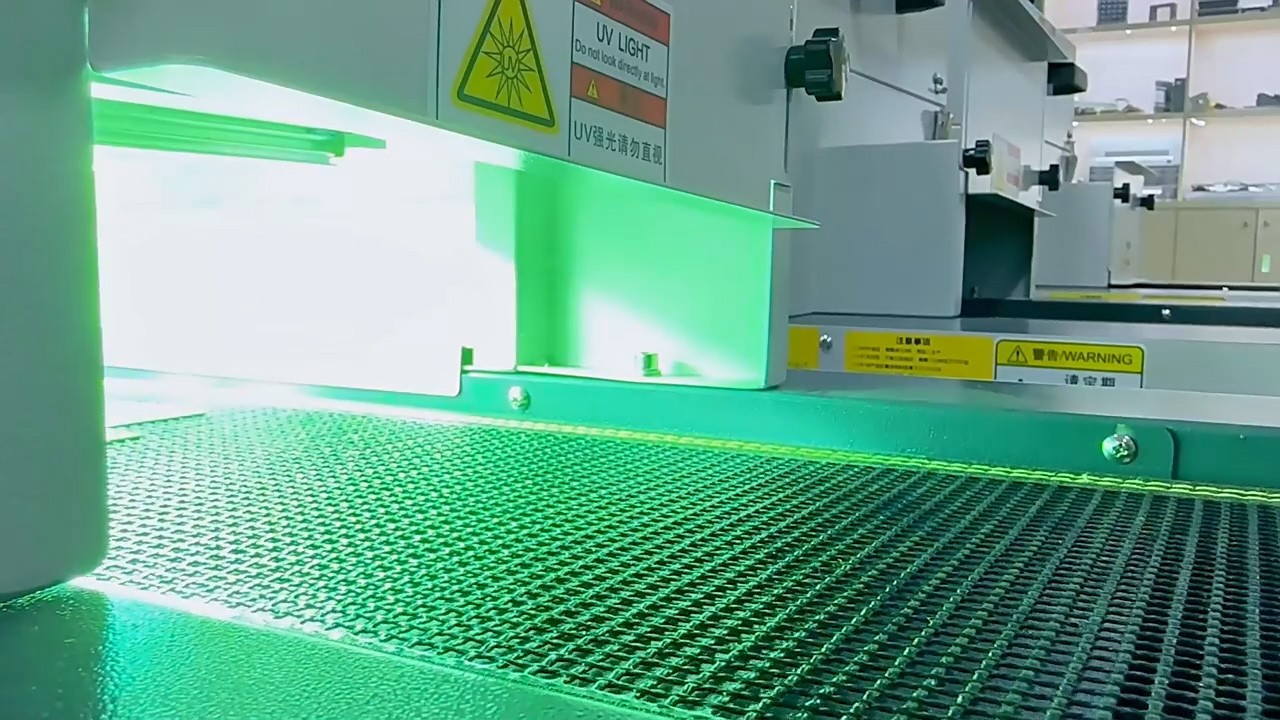

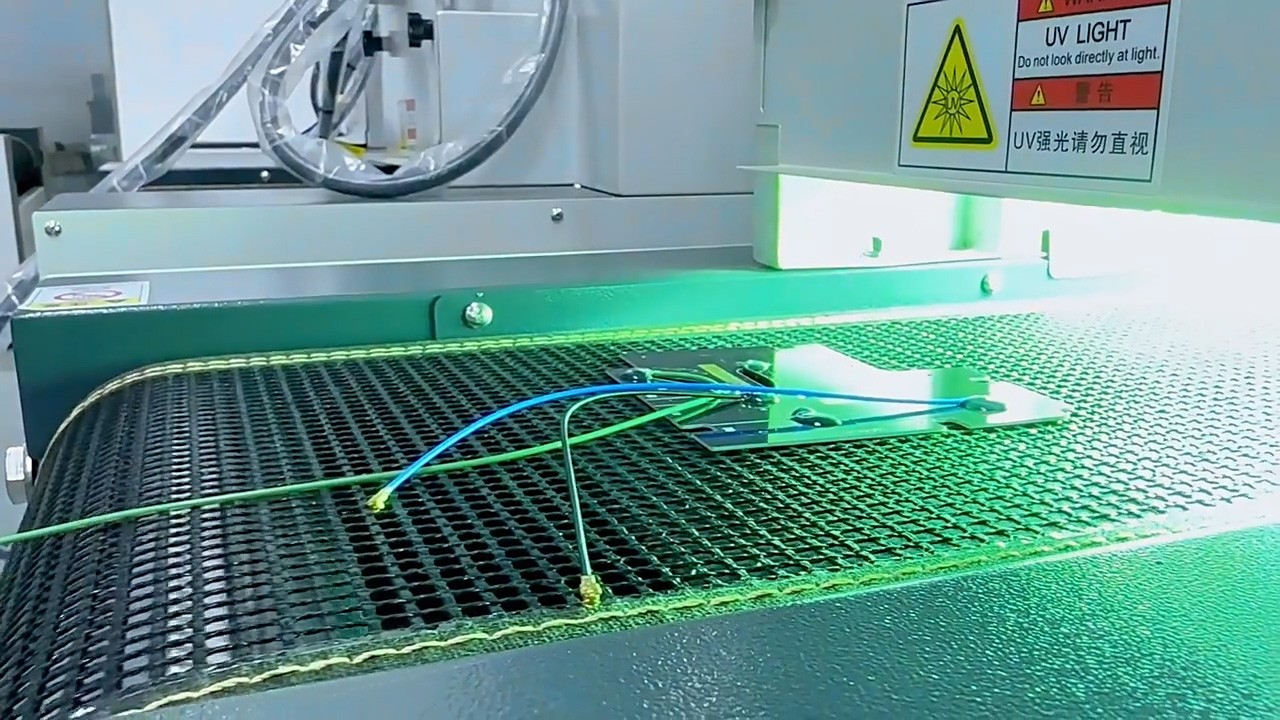

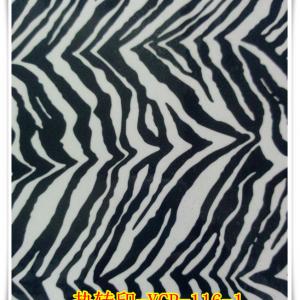

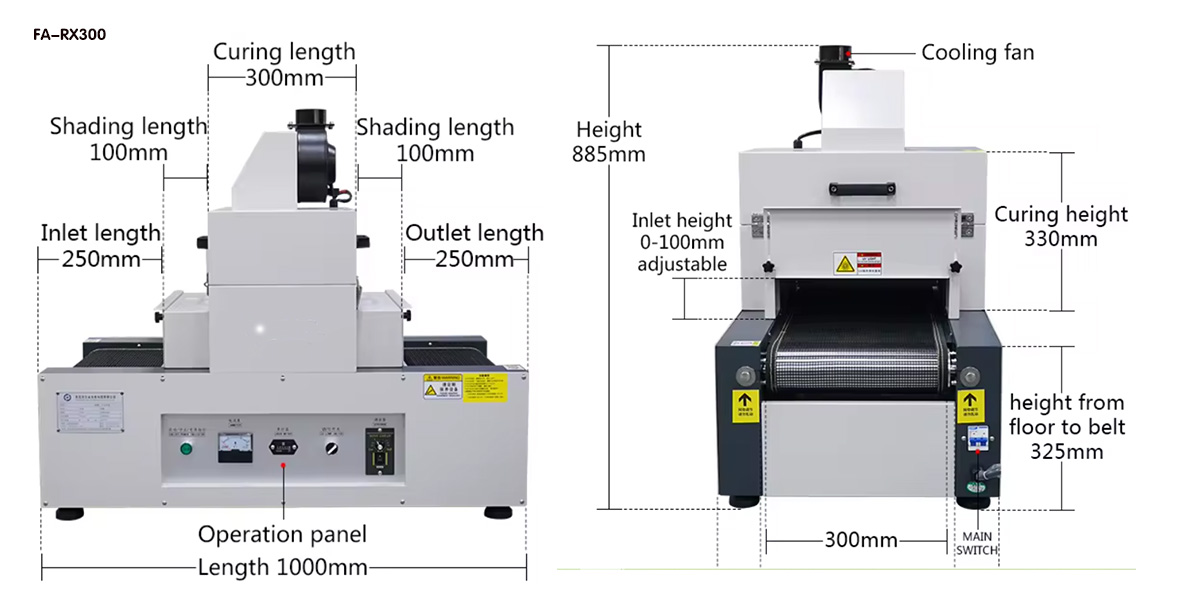

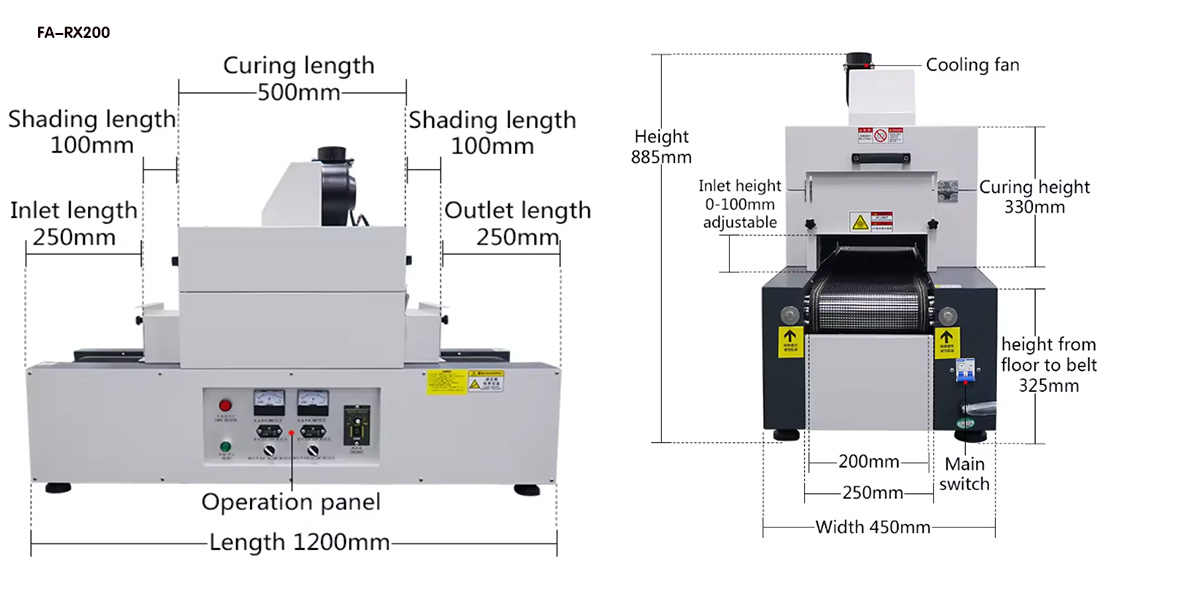

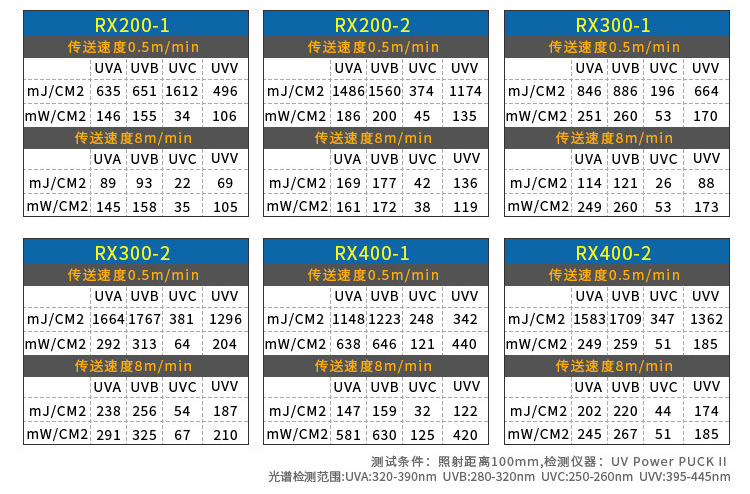

The uv curing equipment/Glue Varnish Drying Machine adopts roller transmission and frequency conversion for stepless speed adjustment, this system uses premium, high-efficiency lamps to reach Instant Drying. The lamp chamber incorporates forced heat dissipation for effective cooling. Its operation is simple and user-friendly and ideal for batch production. Post-drying, the printed surface achieves high hardness, glossiness, scratch resistance, and solvent resistance.

The conveyer speed can adjustment according to the products drying condition;

Conveyer belt mabe by teflon materials;

Famous brand UV lamp installed ;

Cooling fan installed on the side to remove the heat in curing chamber;

Worked on Table, save the space;

Teflon conveyer belt and resist high temperature. function.

Electrical components and control systems using Famous brand to ensure stable Curing quality.

Q: What safeguards are necessary while using the UV curing equipment?

A: It is forbidden to look at the light directly,and do not expose your skin to the light while operation(clothes with long sleeves, gloves and mask are suggested).

Q: How long is the life of lamp tube?

A: The life of homemade tube is 800 hours, and that of imported lamp tube is 1000 hours.(Change the lamp tube depending on the product condition and actual production efficiency.)

Q: What is the wavelength of UV lamp?

A: The common type is high pressure mercury lamp, peak:250-450nm(main crest 365nm)

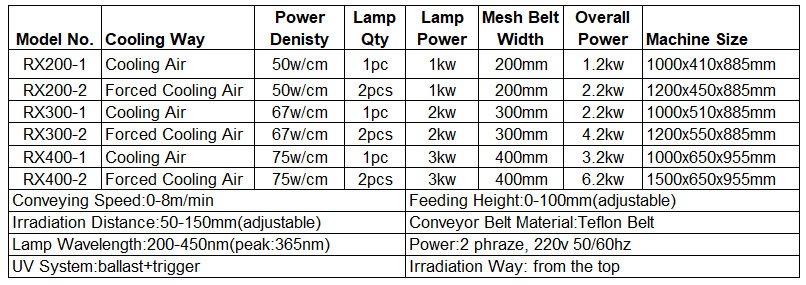

Q: How much energy can the equipment reach?

A:The energy changes according to the illuminating time and distance, and the energy gets stronger while the illuminating time is longer and the distance is nearer.

FA Printing Machine Manufacturer Limited

FA Printing Machine Manufacturer Limited