This automatic Helmet Printing Machine is applied in different industries, including automotive, production, technology, security, sports, etc marketing merchandise. It provides excellent printing results for imprinting a brand emblem on helmet.

Machine Features:

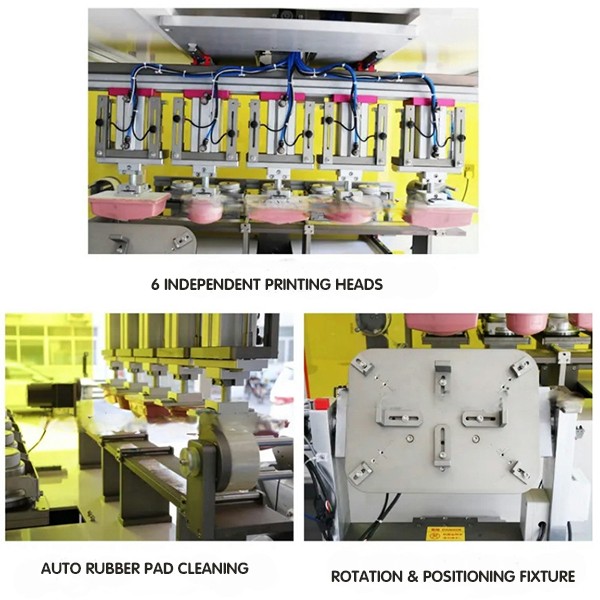

1. This Helmet Pad Printing Machine is able to print workpiece from one color to six colors, With adopting independent printing pads. Which servo driven to the pad to move parallel, back and forth independently.

2. The helmet printer is consisted of four axles servo systems. Machine could be varied with different numbers of axis servo. It depends on different requests to helmet printing. For some helmets with simple printing direction, or to say, few printing area, may modify this pad printer with 2 axles , 3 axles servo motors. And the price is varied accordingly.

3. The printing machine adopts servo driven rotation system, which enables the helmet to rotate different angles for printing. It is programmable support for helmet with 360° rotation

4. PLC pad printing system and servo shuttle control, which can better control the printing position for multi-color printing and color registration

programmable pads cleaning device

5. This pad printing machine uses closed ink cup, which saves ink and protect the environment. The max printing size is 120x120mm. The printing precision to helmet could reach +/- 0.03mm.

6. Automatic rubber head cleaning system can be automatically selected to improve printing quality.

7. Sides of Machine is equipped with grating sensor. During machine working, if worker’s hand moves into the machine, the machine will emergently stop.

8. This pad printing machine is whole assembled and supports tool-less setup, which enables quick job changeover. which reduce labor costs

8. Machine is equipped with CE Certificate.

Technical Parameter:

Model No.:FA-M6/H

Seal Cup Diameter:130mm

Printing Precision:+/- 0.03mm

Max Printing Size:120x120mm

Power:110/220V 50-60HZ

Air Consumption:5-7bar

Printing Speed:300-600pcs/hour

FAQ

1.What is helmet printing machine?

A helmet printing machine is a specialized piece of equipment used to apply graphics, logos, designs, or text onto helmets. These machines are typically used in industries such as automotive, sports, manufacturing, and promotional products to customize helmets for branding, safety, or aesthetic purposes.

2.What need to do before machine printing ?

1) Unpacking and Setup: Carefully unpack the machine and place it in a well-ventilated area, away from direct sunlight and obstructions. Ensure it’s on a flat surface for stability

2) Leveling the Machine: Use a bubble level to ensure the machine is level. Adjust the leveling mounts at each corner as necessary.

3) Connecting Air Supply: Connect the main air supply to the machine’s service unit. Ensure the air is clean and dry, and set the operating pressure to 4-6 bar.

4) Electrical Connections: Ground the machine and connect the main power cable. Ensure the machine is compatible with the local power supply specifications

5) Ink Cup Setup: Install the ink cup and printing plate. Fill the ink cup with ink (up to 80% full) and ensure the lid is securely fastened. Adjust the bleeding screw to allow air to escape.

6) Pad Installation: Install the silicone pad onto the pad holder assembly. Ensure it’s securely fastened and properly aligned for printing.

7) Control Panel Familiarization: Familiarize yourself with the control panel, including the start key, emergency stop switch, and manual mode keys. This will help you navigate the machine’s functions effectively.

8) Starting the Machine: Close all side doors, turn on the power switch, and release the emergency stop switch. Press the start key to activate the machine.

9) Manual Mode Adjustments: Enter manual mode to perform adjustments such as pad stroke and movements. This allows to simulate print cycles and make necessary corrections.

10)Printing Mode: Select a printing program using the program selection keys and press the start key to begin printing.

11. Stopping the Machine: In case of an emergency, press the panic switch to stop all operations.

3. What kinds of helmets could be printed with this pad printing machines?

Our helmet pad printing machines could apply printing on different kinds of helmets, including motorcycle helmets, bicycle helmets, sports helmets, and military helmet, safety helmets ,custom & cosplay helmet. The pad printing process is suitable for helmets made from material like plastic, fiberglass, ABS, PET and other thermoplastics. The ink used in pad printing must be compatible with the helmet material to ensure adhesion and durability.

4.What kinds of printing methods adopt to helmets?

There are many printing methods including digital printing, pad printing, screen printing, heat transferring for customizing the helmets. Our machine adopts pad printing technology ,which is called tampo printing, tampon printing or tampography. It refers to the process of transferring a 2D image onto a 3D object using a silicone pad to pick up the ink from an etched plate and then deposit it onto the surface of the object. This method is highly valued for its ability to print on complex and uneven surfaces, which is why it's commonly used in industries such as automotive, medical, and consumer goods for branding and decoration purposes

5. What is the advantage of using pad printing machine for printing helmet?

Pad printing can be used on a wide range of helmet surfaces, including curved, textured, and irregular shapes, which is ideal for the complex geometry of helmets . The technology allows for high precision and detailed prints, ensuring logos, designs, and safety information are clear on the helmet

6.How to print logo on helmet by this pad printer?

1) Prepare the Printing Plate---Setup of the Pad Printer---Inking the Plate---Transfer of Ink to the Pad---Curing the Ink(if necessary)---Quality Check---Repeat or Continue---Cleaning and Maintenance---

7. How to maintain the helmet pad printing machine?

1). Lubricating grease must be added to the moving parts of the machine once a week.

2). The moisture in compressed air should be filtered thoroughly to prevent it from entering the cylinder and reducing the service life of the cylinder and solenoid valve.

3). Pay attention to draining the accumulated water in the water compartment after each shift,

4). Keep the body clean and regularly clean the ink adhering to the surface.

5). At the end of each workday, it is necessary to turn off the machine power and clean the oil cup and steel plate quickly. Add some oil or butter to the steel plate and cover it with cardboard.

We have everything you need for pad printing, whether you want to mark, decorate, or label a product. Visit our Youtube channel to learn more.

FA Printing Machine Manufacturer Limited

FA Printing Machine Manufacturer Limited