How to Make the Pad Plate/Steel Plate? How to Etch the Cliche Plate?

---Before Making the Pad Plate---

1:Laser Imagesetter

Due to the importance of making a film design before proceeding with pad plate engraving, we should well prepare the good quality film as a beginning. Hereby, we offer FA-310 Laser Imagesetter for pad printing,

Laser Imagesetter

Brief procedure as below

1)Design

Design the drawing with computer as Coreldraw and other corresponding design format.

2) Cut film

Cut the film with blade to be suitable for the imagesetter machine.

3) Output

Set the film on the working table of the imagesetter and operate computer with RIP programmer installed.

Note: The film installation and adjustment should be done under dark green safelight in a darkroom to avoid film exposure.

4)Developing

Take out the film and dipping into developing disk for some minutes

2:Cleaning Treatment:

Cleaning the pad plate with solvent or alcohol .Do not use the plate before complete solvent volatilization. All process must be going long in the safe light of red light or yellow light

---Plate-Making Process---

3: Coating

There are many method to coat emulsion onto to pad plate, for example, by turning coating machine, by dipping coating machine, by spraying coating machine, by manual coating tool etc. However, in order to evenly place the emulsion on plate surface, we could hand handle it before putting into emulsion machine.

Here below we talk about the most common way by using the turning machine for emulsion coating.

Fuji Coating FMR-40

Fuji coating is one kind of native sensitization Emulsion with high precision solution.Film will be formed after coating onto pad plate by turning coating machine. it is important Chemicals in the process of making pad plate.

Emulsion Coating Machine For Pad Plates FA-M-220T

1) Put the pad steel plate on the turning disk and fix it according to operation manual (as as attached picture)

2) Pour some Fuji emulsion to surface of the plate

3) Press on the START button of the emulsion machine and adjust the speed so that the emulsion coating to the pad plate evenly

5:Drying

Drying the pad plate in a drying closet after coating Fuji emulsion . Set a temperature at 100-150 degree for 20 minutes. You may use hot air blowing for hair to dry the steel plate. Drying emulsion process will protect the plate from etching in the next step.

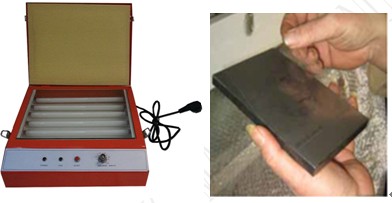

6: Exposure

1)Setting the film to cover the emulsion steel plate in exact position , please remind that the image should be in accord with printing requirement, avoid of air in between and adhere the film and plate by using kind of tape along edge.

2)Place the steel plate (cover with film) on the UV glass of exposure machine and close the cover with lock

3)Set the right exposure time and turn on the Start button for exposing purpose

Note: Please let UV light pass through film, correcting setting time is very important to ensure the precise exposure quality. We suggest you testing 5 kinds of different exposure time to find the correct exposure time.

UV Exposure Machine

This is kind of UV Exposure machine FA-T280SB. It features with its auto exposure function. After setting correct time, the UV light start exposure and the UV light will be automatically off after finish exposure.

7: Developing

1)Developing with FMR developer for 60 seconds at the room temperature and starting washing.

2)Pouring FMR developer into developer tray/bucket, please note the developer should be more than the plate thickness in order to dip the whole pad plate.

3)Shake one minute continually until the image is displaying clearly after dipping the plate into developer

FMR Developer

8:Washing

Water washing the plate completely to remove the developer and solvent emulsion. Remains of developer and

emulsion will damage the image during etching

9:Drying

Repeating the drying procedure by the same closet at temperature of 50℃ for 20-30 minutes to not only dry water, emulsion, but also enhance the emulsion adherence

10:Etching

Start etching by using the etching liquid. Brushing the liquid on the exposure area of the pad plate for 40 seconds. Here we suggest to use etching machine for achieving the better etching quality.

Etching Liquid Brush Manual Etching

11:Removing

Use FMR removing or solvent liquid to remove the remain film on the pad plate and clean it with water

12: Depth measure

The depth is the way to measure the quality of the pad plate. By putting the pad plate on the flat table of depth measuring machine, we could measure it with standard depth of 21um. It also varies to different customers.

plate on the flat-Table of depth measure meter, standard depth is 21um. But different customer need different depth.

13: Package

After finishing all process of making pad plate:

1) remove all remains by soft fabric with solvent and put into bag

2)Spraying anti-rust oil to protect the pad plate

For More Information about the Pad Plate Making , please visit as below

Plate Making Equipment Pad Printer Machine

FA Printing Machine Manufacturer Limited

FA Printing Machine Manufacturer Limited